Is Silver Used In Solar Panels? How Much Silver Is Used In Solar Panels?

Commercial as well as residential photovoltaic (PV) solar panels have been on a steady rise over the past year. In the United States, federal tax incentives for those adopting renewable energy expire this year, so customers are trying to use up the credit while it is still around. The goal is bifurcated- save money and reduce carbon footprints.

This expiration date has prompted numerous impulse buys, and web searches regarding solar panels have consequently increased. One of the most common questions renewable energy owners asks is, “is silver used in solar panels?” and if so, “how much silver is in a solar panel?”

In this article, we will try to get to the bottom of this. We will outline all about the amount of silver used in solar panels and everything else you might want to know about it.

Do Solar Panels Need Silver? Why is Silver Used In Solar Panels?

Silver is a conductive metal that is appropriately qualified for energy production. As the most electricity-conducting metal on the planet, silver is relatively fire-safe and holds the 100-level productivity placement, where 0 is the least efficient. Silver is also a light metal, which allows roofs to withstand the panel’s weight.

Currently, panel efficiency levels range between 15 to 20%, making silver a decisive factor for energy production expansion. Studies foresee technological advancements to amp up solar panels’ electricity outputs.

Increasing the efficiency of solar panels while reducing the quantity of silver used requires PV research where scientists can use near-infrared spectroscopy to see the reflectivity of certain materials. Glass reflectivity studies are still ongoing. The goal is to find viable replacements for silver in solar panels.

President Joe Biden has put forth plans to expand renewable energy sources from the present 2% of solar consumption. As and when efficiency rates are amped up, and prices are lower, commercial as well as residential solar purchases will begin growing.

How Much Silver is Used In Solar Panels?

In the year 2020, the world supply of silver was no less than 976.2 million ounces, which became an estimated 1,056.3 million ounces in the year 2021. This is as per the Silver Institute. The overall global silver demand in the year 2020 was 896.1 million ounces, and the 2021 estimate totaled a whopping 1,033.0 million ounces.

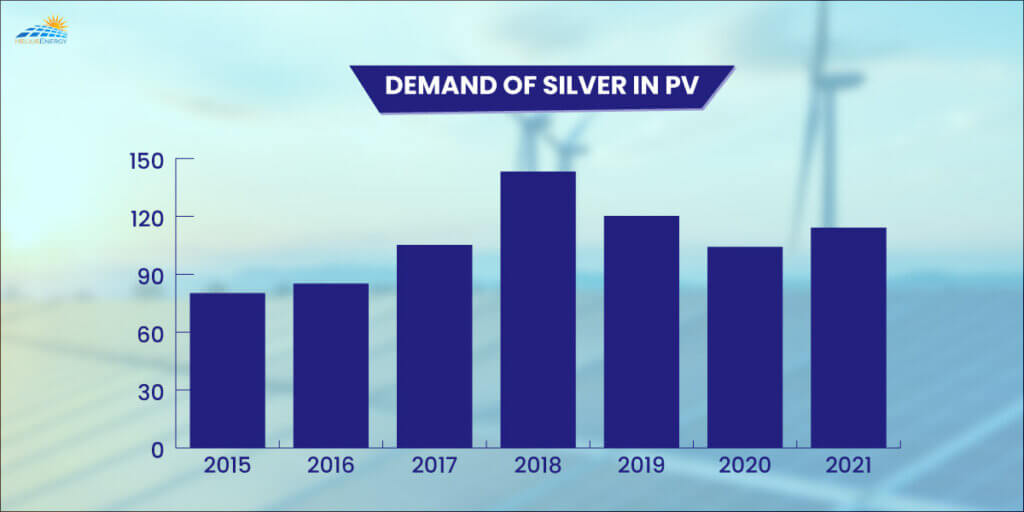

In the early 2000s, the demand for silver from the solar sector barely even registered, covering less than 1% of silver demand. But in 2019, the photovoltaic (PV) sector accounted for no less than 10% of the total silver demand, making up 98.7 million ounces within the total silver demand of 991.8 million ounces. This is as per the Metals Focus data.

Going by the We Recycle Solar website, silver is predicted to use up to 6% of the total cost of creating each solar panel unit, with the average panel of approx. 1-meter sq. using up to 20 grams of silver.

According to 2018’s data, the solar panel manufacturing industry has already used about 8% of the world’s yearly physical silver supply. The London-based consultancy CRU thoroughly explored the relationship between the demand for overall solar power, juxtaposing it with the market trend of silver.

Can Less Silver Be Used In Solar Panels?

According to the CRU study, the photovoltaic (PV) sector will continue to consume 81 million ounces of silver annually over the next decade. Here’s something interesting- much more silver was used in 2019 in making photovoltaic cells (100 million ounces). What does this drop suggest? It implies that the market demand might have peaked in that year.

Photovoltaic cells made of alternate materials apart from silver, aluminum, or copper have proven less reliable. This poses a significant challenge for the commercial progress of all non-silver PVs. Leading manufacturers are, however, trying to make headway towards a viable resolution.

What Does The Future Hold?

A major German research group, Florian Clement, the group head of solar cell printing technology at the Fraunhofer Institute for Solar Energy Systems, ISE, expects the industry to be able to lessen its use of silver per cell by half over the coming decade. Clement says, “A reduction of 50 [milligrams] per cell is still expected to be possible within the next 10 years.”

This reduction and alterations to the pace of global solar installations are decisive drivers in the forecasted drop in the silver demand from photovoltaics, as suggested by qualified analysts with the CRU Group and Metals Focus.

Conclusion

Sure, it might seem like a rather simple change to move the wires to the back, but the sheer tendency of solar cells is for the electricity to seamlessly flow out the front, that is, the sunny side. Therefore, making rear contact solar cells work emerges with their manufacturing challenges, which is mostly why they are limited to only premium solar panels till now.

Still, you will always find ongoing innovations in solar panels, and expansive research is still underway in reducing and eliminating the use of silver.